Attain greater architectural freedom while maintaining structural integrity.

The most cost-effective and narrowest prefabricated shear wall panel in the industry, the MiTek Hardy HFX Shear Panel enables narrower walls and larger openings. The MiTek Hardy “C-Shape” allows trades to insulate and recess fixtures easily.

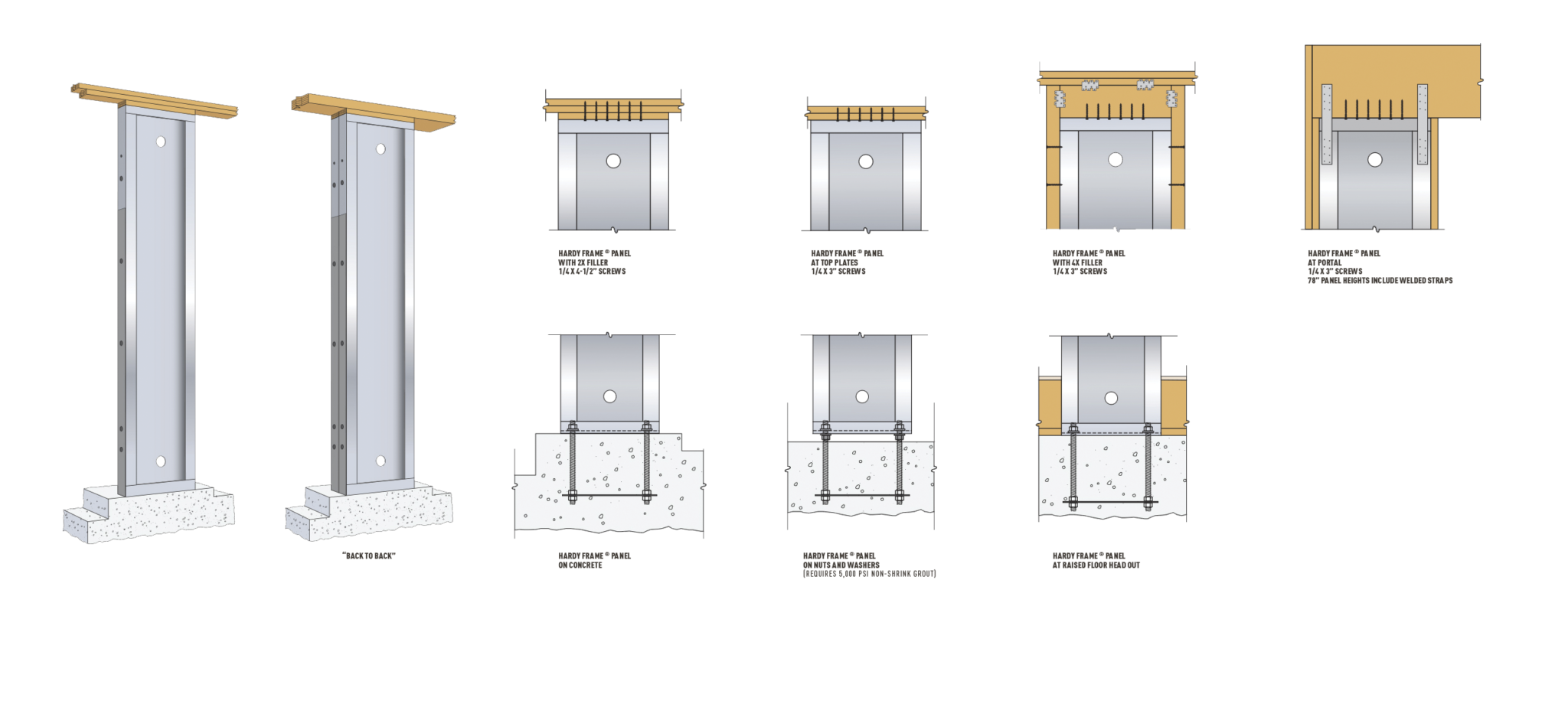

MiTek Hardy Shear Wall Panel on Concrete Foundations

- Installation on nuts and washers provides for leveling at uneven concrete – and an open end box wrench may be used to secure connection from below. Allowable loads are less than installation directly on concrete. Confirm with design building professional prior to installation.

- Raised floor head out installations bypass wood framing to eliminate the effects of shrinkage and crushing, while providing a direct shear transfer to the foundation

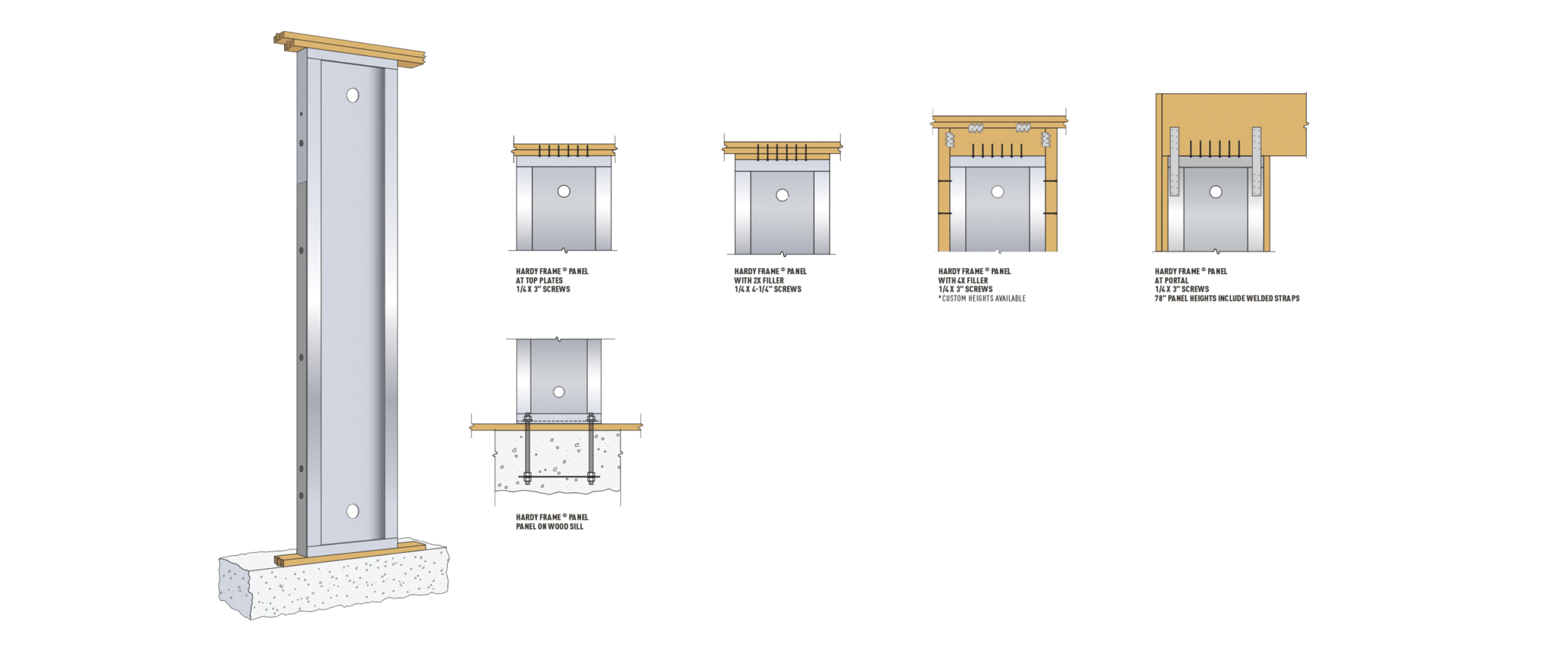

MiTek Hardy Shear Wall Panel on Wood Sill Plate

- Panels installed on wood sill plates have more ductility but, for some sizes the allowable shear is less to account for crushing of wood below

- Allowable values have been reduced when necessary to maintain code drift limit (see HFX-Series Product Catalog Table 1.2)

Installation:

- Set bolts 4-1/4″ inches above concrete

- Moisture barrier (15# felt, Moist Stop, Etc.) recommended when installing on treated wood

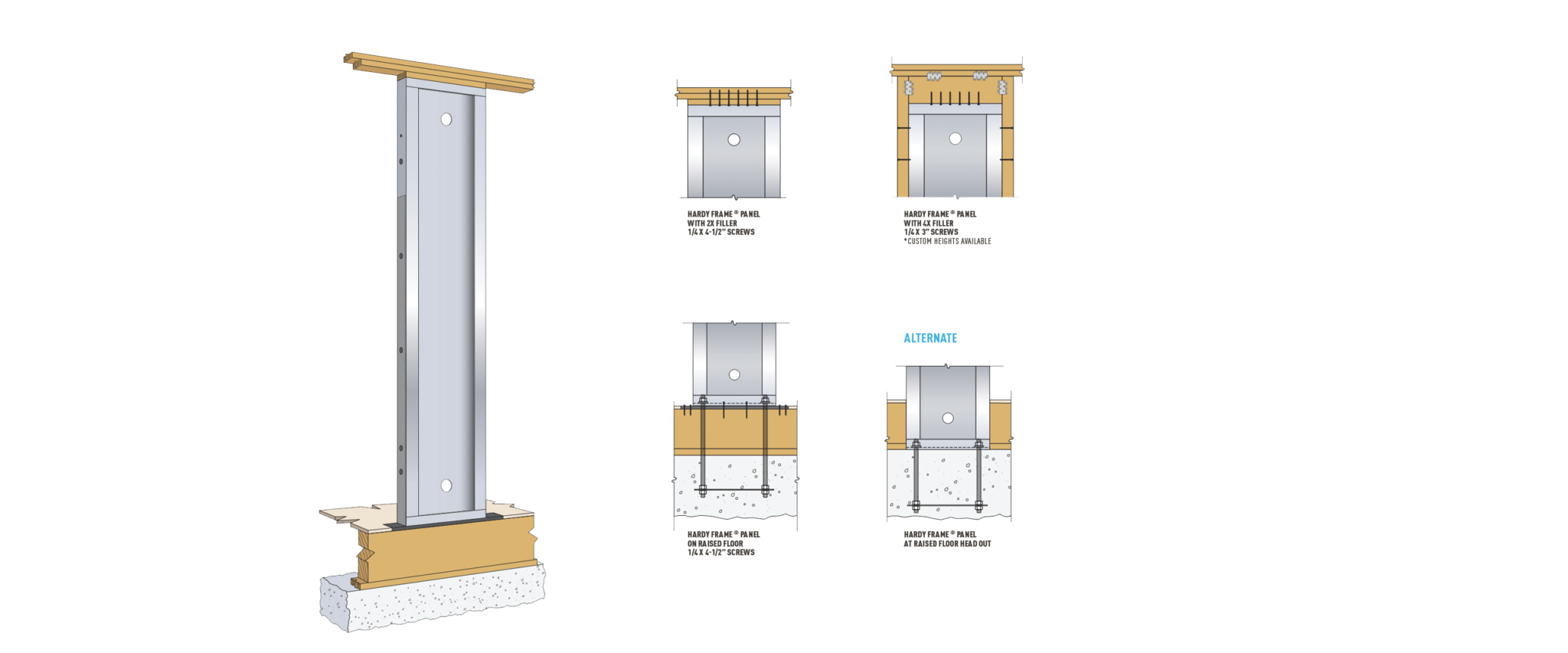

MiTek Hardy Shear Wall Panel on Raised Floor

- Allowable values have been reduced when necessary to maintain code drift limit (see HFX-Series Product Catalog Table 1.3)

- Table values for Panels installed on a wood floor system assume installation with a Hardy Bearing Plate

Installation at raised floor head-out:

- Provides allowable values from HFX-Series Product Catalog Table 1.2A

- Provides a direct shear transfer to the foundation

- Requires less material by eliminating rim, Bearing Plate and bottom screw

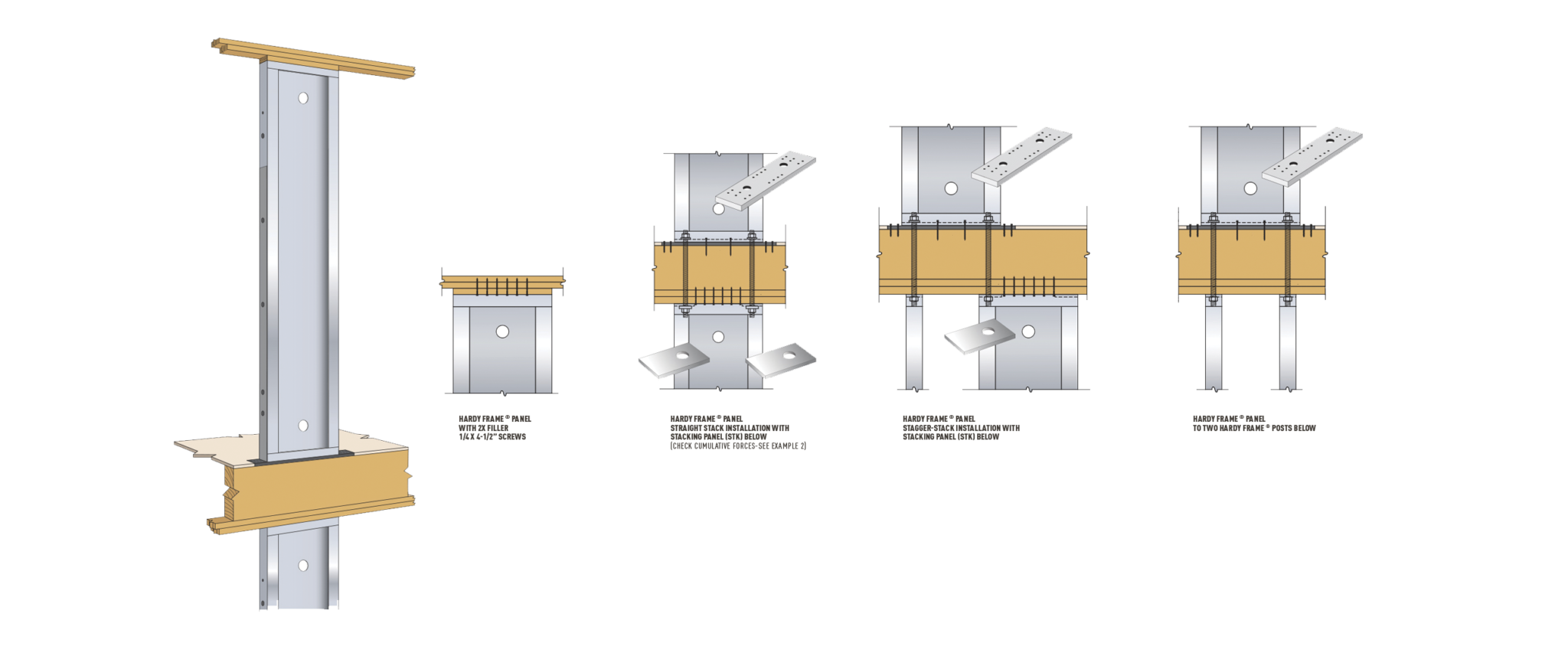

MiTek Hardy Shear Wall Panel on Upper Floor

- Allowable values in Table 1.3A have been adjusted to maintain code drift limit while including the effects of crushing in wood members below.

- For “straight stack” installations, cumulative forces must be considered by the building design professional.

- For discontinuous systems, amplification factors must be considered by the Building Design Professional.

- Table values for Panels installed on a wood floor system assume installation of a Hardy Bearing Plate.

- For installations on beams, size plate washers on underside of wood beam to prevent crushing and include deflection from the overturning couple in the drift procedure.

MiTek “STK Washers” are required in the top of Panels when connecting to a hold down rod from above. MiTek “STK Panels” include pre-welded in the top channel.

MiTek Hardy Shear Wall Panel For Cold Formed Steel Framing (c-fs)

- HFX/S Series products are manufactured to cold formed steel stud heights. Nominal 8′ heights are 96 5/8″ net, nominal 9′ is 108 5/8″ etc.

- Installation can be directly on concrete (moisture barrier recommmended), with a c-fs channel below, on a nut and washer for levelingor height adjustment up to ±1-1/2″ when approved by the Building Design Professional

- Top connections are made with 1/4″ diameter self tapping screws after installing floor or roof members above

- Panels are 3-1/2″ net depth